Cut Total Lifecycle Costs by at least 20%

Infrastructure will change. The model with 1% margins cannot be sustained. InfraLytics is thé tool for operators in the civil infrastructure space to step into a recurring revenue model and avoid becoming a player from the past.

InfraLytics is the ideal tool to:

- Bring long-term recurring revenues to contractors

- Reduce risks and total-lifecycle cost for governement, authorities and private investors

- Reduce carbon footprint and increases sustainability as operational life of assets is prolonged

Infrastructure as a Service is coming

You'd better be well equipped!

As the construction world suffers from low margins, the world of 'Smart Cities' emerges. The end result will be smart infrastructure, that will be made available to its users or authorities through a subscription model: Infrastructure as a Service. This model will increase financial resilience, but needs a dedicated tool for close follow-up and monitoring of how the assets are doing and where to intervene to avoid standstill. The end result is an infrastructure that is continuously in an optimal shape, with minimal maintenance costs and a maximal operational life: ultimate sustainability.

Availability is key !

Reduce failures & risks

When operating in a recurring income model, availability is key. Major repair works are a nightmare for owners and users. These are avoided by acting exactly when necessary: at the moment where the degradation is still in an early stage. In a DBFM or PPP scheme a reduced availability directly hits the bottom-line. This is avoided using a dedicated monitoring platform that provides learning based on historical data to generate predictions on the asset health. Replace expensive and lengthy inspections & maintenance jobs by targeted and short data driven inspections and repairs.

Know the actual remaining lifetime and asset value

Data is power

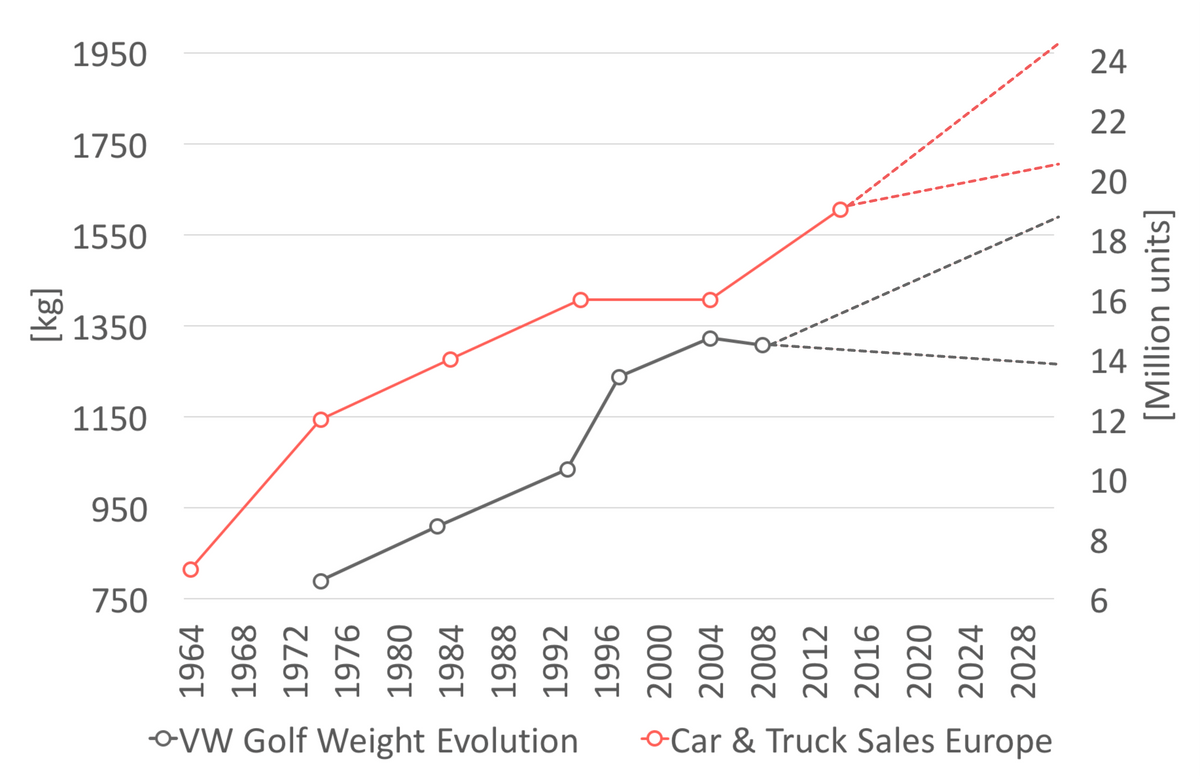

Infrastructure is built to serve the community for a long time. Traffic loads and usage types however evolve continuously: supertrucks, autonomous cars, climate change... As such predictions on actual operational life become increasingly challenging. Assessments on remaining lifetime and maintenance needs have to be based on true loads and usage, not on assumptions from the design phase. This is a prerequisite for proper lifetime extension or when designing and executing of necessary repair or reinforcement jobs. The integrated approach ultimately determines the capital value of the asset. You'd better do this continuously and with the smallest possible degree of uncertainty: through monitoring.

Create a true Digital Twin

Combine data and models to increase knowledge

Structural and Finite Element models are essential tools to design structures and predict their operational performance. Actual behaviour however always deviates due to imperfect knowledge of surrounding conditions and inhomogeneities in materials and joints. A Digital Twin is the ideal tool to track the structure over its entire lifecycle. Sensor-based continuous follow-up allows the owner to match the Twin’s behaviour with what is actually happening. Combining physics and data science allows operators to engage in profound asset criticality analysis.

Perform maintenance ... in time!

And avoid disaster

A visible crack in the concrete surface may be an indication that things are not going as planned. Most often it is not enough to just cover it up. Cracks in concrete originate from internal disintegration, corrosion or (external) stresses. Based on multi-aspect monitoring, dedicated sensors and the appropriate correlation analysis you can solve the root cause rather than treat the symptoms. Recent incidents such as the one Genoa, Italy (Morandi bridge) can be perfectly avoided if a proper continuous follow-up is implemented.

- Features

What InfraLytics brings to the table

Infrastructure 4.0

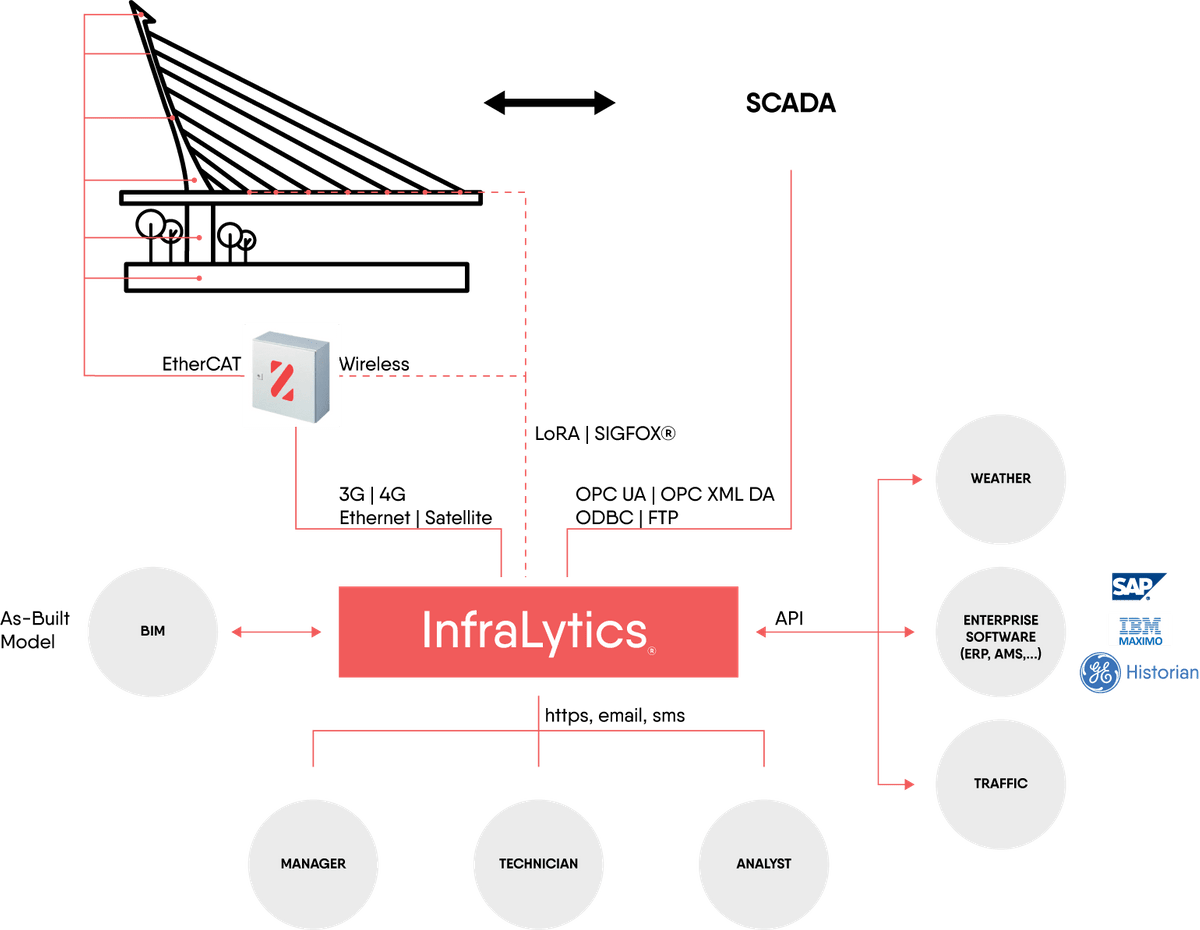

InfraLytics®️ is a turnkey, end-to-end infrastructure integrity management solution that combines state-of-the-art sensors with comprehensive data ingestion, profound data analysis methods and insightful dashboarding. Making use of advanced data science approaches such as trained Neural Network models as well as well-known physical laws describing for example fatigue life consumption advanced insights are generated, continuously.

Unlock value from data lakes

InfraLytics®️ continuously and automatically combines and analyses data from multiple sources to provide hands-on diagnostics & recommendations for asset maintenance:

- Structural Health Monitoring: On-site sensors for displacement, vibrations, total stations, deformations, strains, Integrizen®️ for concrete integrity, environmental sensors,...

- BIM: use meta-data from the As-Built BIM model to efficiently relate sensor data to item location, material properties, sensor positions, data sheets,...

- Asset Management Data, Inspections & Repairs: inspections reports, statistical analysis, images & video/audio recordings, work order logs...

- Traffic: density, speed, vehicle classification,...

- Weather: current conditions, predictions,...

- Electrical / Mechanical / Hydraulic Systems: logfiles & SCADA output from actuators, pumps, ventilation systems, motors,...

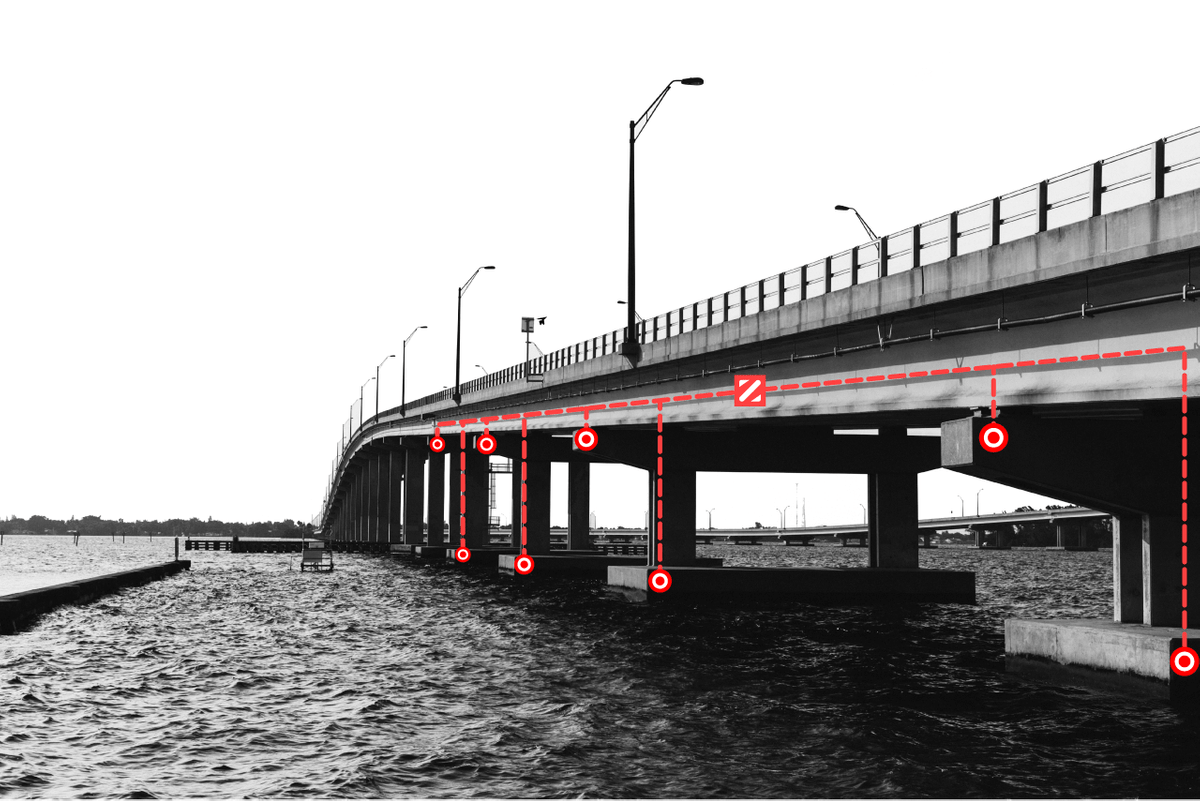

Retrofit your existing assets

InfraLytics®️ can be installed on your existing assets and provides insight on deterioration phenomena which have been undetected so far. All required hardware is easy to install and can be operational within hours.

Infrastructure assets that can benefit from InfraLytics®️ are, but not limited to:- Bridges

- Tunnels

- Airports

- Railroads

- Locks

- Dikes & Dams

- Underground structures

- ...

Open & Vendor Agnostic product

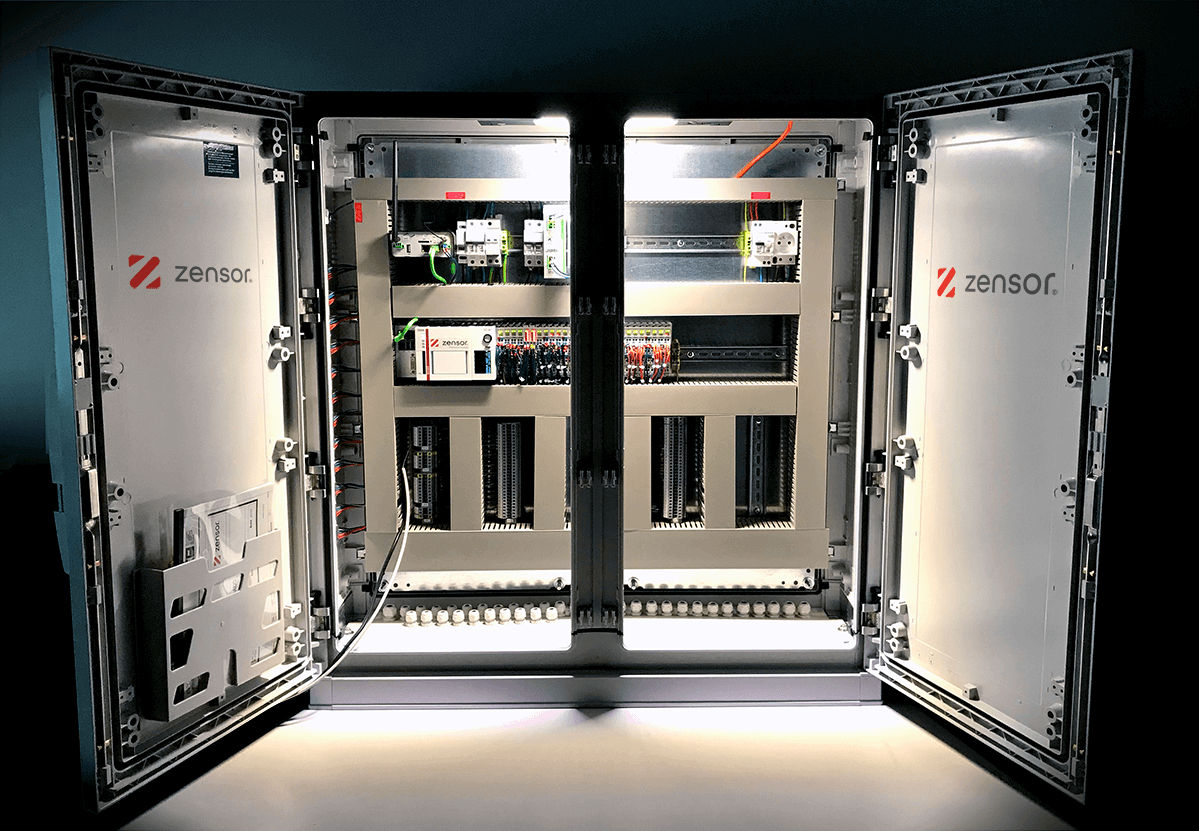

Why stick to a single provider of SHM sensors, data acquisition system or data provider? Reap the benefits from selecting the right technology for each phenomena or application. Whether you need to integrate existing, legacy sensors or you want to combine multiple cutting-edge sensors together, all data is treated and stored in uniform ways.

Our data acquisition systems are based on industry-class hardware with open and standardized protocols for I/O and control.

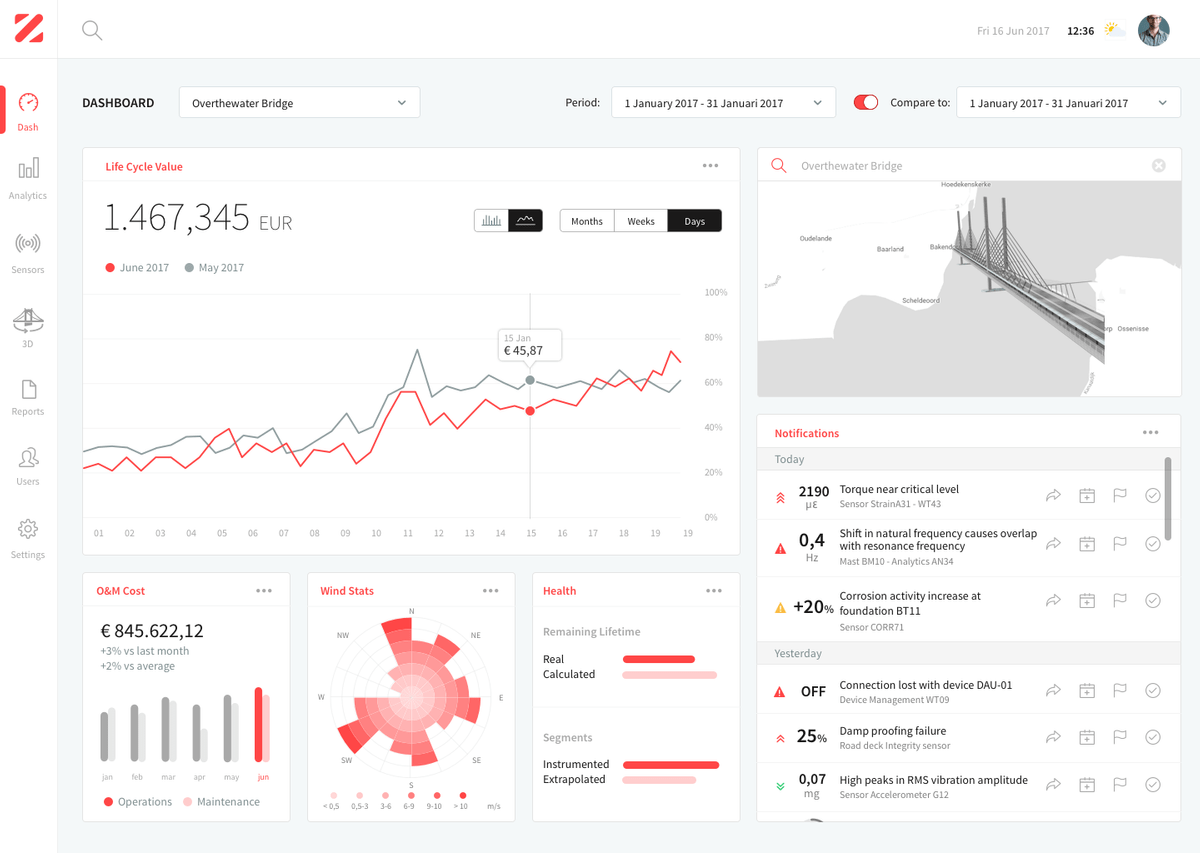

InfraLytics®️ Dashboards

Keep an overview on your portfolio's integrity from our browser-based InfraLytics®️ dashboard. Combined with additional data sources as BIM, weather, SCADA or traffic information, the integrity data is processed and analysed to provide valuable decision support.

Through big data analysis & machine learning, the multi-parameter data is converted into clear ROI and remaining lifetime insights. Well-planned and executed actions are executed based on data, not on opinions.

Phenomena

Relevant phenomena are: Concrete Cracks, Fatigue, Traffic loads, Corrosion, Bolt tension, Weather impact, Stray currents, Ground water movements, Inclination, Concrete cancer, ASR, Tilt, Deformation, Currents, pH, Temperature, Pressure, Settlement, Strains...

Sign up

Be the first to receive upcoming brochures, white papers and use cases from InfraLytics

Contact

sales@zensor.be

Witte Paterstraat 4

1040 Brussels, Belgium

+32 2 737 67 32